aerospace suppliers:

Are you overspending

on your facilities?

Aging facilities can lead to costly workforce challenges

Outdated facilities can detract from your existing workforce and can cause hiring issues, especially as you seek to hire younger workers. A detailed cost/benefit analysis of your facility can help you find affordable improvements you can make today, to boost employee satisfaction and retention for the long-term.

$16-30K

employee replacement cost

Poorly-planned equipment changes can cost you dearly

When considering an equipment upgrade, it’s important to note that existing facilities are often ill-equipped to support new technology and equipment. A thorough assessment of your infrastructure’s conditions can give you much needed visibility into the realistic requirements of modernization.

$3M

infrastructure impacts

Hidden issues can strip serious value out of your M&A deals

If you’ve recently gone through M&A, there may be hidden costs and other issues within your newly acquired assets. A comprehensive review of your real estate and facilities portfolio can tell you what it’s really costing you and identify anything that may have been missed during due diligence.

$38M

unexpected maintenance

Energy-intensive processes can generate intense cost leaks

Aerospace manufacturing can be an energy-intensive process. If you’re not paying close attention, you may not realize how much that energy is costing you. An in-depth energy audit can alert you to costly inefficiencies, and a detailed energy reduction strategy will give you a roadmap to correcting them with a focus on ROI.

$673K

annual energy waste

Dive Deeper

Continuous Improvement

Discover how one aerospace manufacturer

improved margins through a successful

Continuous Improvement journey.

EXPLORE EVIDENCE

We built an amazing facility together.

I think it's something we can be proud of forever.

Jennifer Ray, Program Manager

Woodward, Inc.

(An aerospace and industrial design and manufacturing company)

CASE STUDY

Facility Transformation

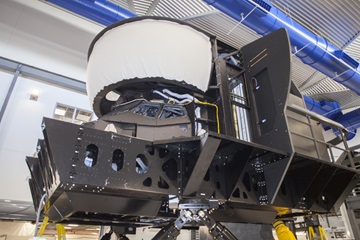

See how expansion/renovation improved process flow and flexibility, removed unused workspaces and modernized test lab into SRF institute with particle accelerator.

CASE STUDY

Equipment Optimization

Learn how a perfectly-planned equipment move saved an aerospace supplier over $3 Million in potentially lost wages and reduced downtime by 20% overall.

CASE STUDY

Develop-Design-Build

Find out how this aerospace manufacturer had support on site selection, entitlements, programing and design – all with meaningful guarantees on total cost and delivery dates.

Develop-Design-Build-Optimize

Today's competitive aerospace environment requires unshakable focus on delivery and radical innovation in how structures and facilities are built, managed and maintained.

Our team is ready to discuss your develop-design-build needs for acquiring land, leasing, owning or simply updating your space.

Whether you plan to build new, expand your production floor, update your space, modernize your machinery or relocate your HQ, we’re here to help you identify opportunities to maximize your savings, optimize your investments and take your next step with confidence.